NEW T&S BLOG!!!

March 2, 2016

The Search for Efficiency Pt. 2

April 26, 2016In 1982 I decided to open my own engine rebuilding shop. I had worked for Wayne Calvert Precision Engines, the most reputable performance shop in the North Central Texas area, and I figured at the tender age of 21 that this qualified me to have a successful business. I had no guidance, no business training, no capital of my own, no building, and no customer base. But I had knowledge and good mechanical talent. With that talent I believed I would develop the rest.

My plan was to find machines, find a building, set up shop and crank out work. I really didn’t have much more of a plan than this. I thought I would be completely covered up with work once the public discovered me.

Since my bank believed in me (banking standards were lax in the early ‘80’s) I was able to borrow the necessary funds to get set up. That is, as long as I found the right deals on the machines.

I made a fatal mistake when I chose the machines. In my mind, it didn’t matter what machines I procured; I would be able to make them work. I had very little knowledge of any machines outside those in the shop in which I had worked. It seemed that any machine would do. I purchased the slowest boring bar on the market, but it cut on size and left a great finish. I bought a slow surfacing machine, but it was versatile and considered one of the best. I found an old crankshaft grinding machine and taught myself to grind. I had to have a rod hone and gave little consideration to whether there was another method that might be faster with the same accuracy. I purchased and old valve grinding machine that was also very slow but left a great finish. I picked up a seat grinding set and a knee mill for a bit of versatility. With these choices I did some nice machine work and I still believe today that the product I sold my customers was as good as they could get. However, I set myself up for failure from the beginning.

I did some beautiful work and built some really nice engines, but I had no idea how to make money. I tried to make up the shortfall by working more hours. I learned quickly that when you are losing a dollar on each thing you sell, you do not want to sell a million of them.. I also learned that you cannot swap dollars and maintain a business. I found that satisfied customers and a good reputation stroked the ego but would not pay the bills. I worked and worked and could not figure out what was going wrong. It would be many years before I would understand how common this story is in small business America and especially in the automotive engine industry.

I have been in many machine shops in the last 35 years and I have seen many examples of tradesmen working themselves to death. I have also been privileged to see those who learned to make the business work and they do it with efficiency.

Many shop owners think nothing of hiring another employee but cringe at the thought of spending money on machinery. The interesting thing is, the machinery pays off in a matter of time; the employees don’t. The cost of one employee per month is enough to cover a payment of $150,000 worth of equipment on a 5-year lease. After 5 years, the equipment will keep working without needing a paycheck! A shop can become very efficient with the right machines.

This does not necessarily mean employees are not needed. What it does mean is that it’s necessary to tool the shop for efficiency before hiring more employees. If business is done in this order the employees will not cost money. They will be efficient enough to make the shop money. Without the machinery, there is a real possibility that no matter how many employees are hired the cash-flow will be very minimal.

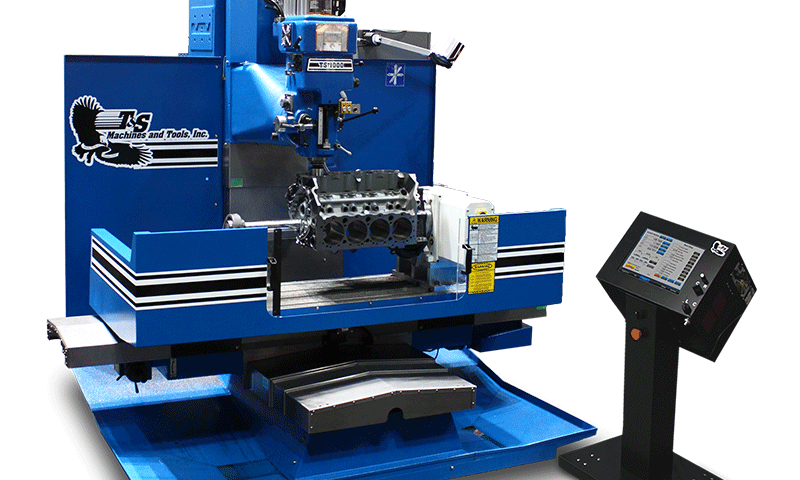

The shortest answer to the efficiency concern is to use automated machines. With automated machinery work is able to be turned out on more than one machine at a time with a single operator. This is where the cash-flow begins to turn positive. When I can take a very good machinist and make him more efficient with an automated machine I can increase my production and use fewer employees doing so. I can then pay my help what they deserve to be paid and I can turn out more consistent work without the downtime of finding and training new people.

This is the business we should all seek to have.

Thank you for reading and I look forward to hearing your comments below and on facebook! Check back with us soon as we highlight a long time customer of ours, Howard Anderson at ARFabrication, and show how he is putting these ideas into practice in his own shop.

Regards,

Tim Whitley, Sr.

1 Comment

Gracias por su historia. Espero poder realizar mi sueño utilizando máquina TyS