PB-L500 Deluxe Crankshaft

Balancing Machine

The ProBal Dynamic Balancing PB-L500 offers an advanced solution for crankshaft balancing, ensuring peak performance by precisely measuring and correcting imbalances. Its adaptable modular design and comprehensive features evolve with your workshop’s requirements.

Opting for ProBal Dynamic Balancing in your crankshaft balancing endeavors signifies more than just selecting a machine; it represents a dedication to superior quality, continuous innovation, and progress. Embrace the future of industry excellence with ProBal.

CRANKSHAFT BALANCING MACHINE PACKAGE

- 22inch Touch Screen Display

- Windows 10 Operating System

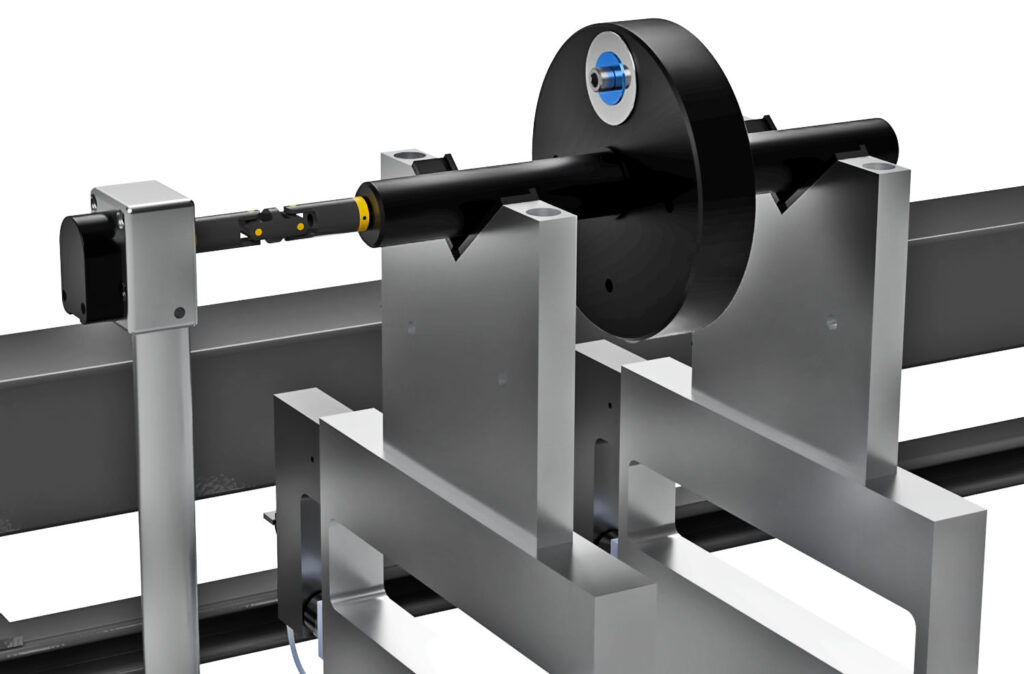

- Exclusive Overhead Drive System

- Bobweights

- Rod Weighing Setup

- Digital Scale

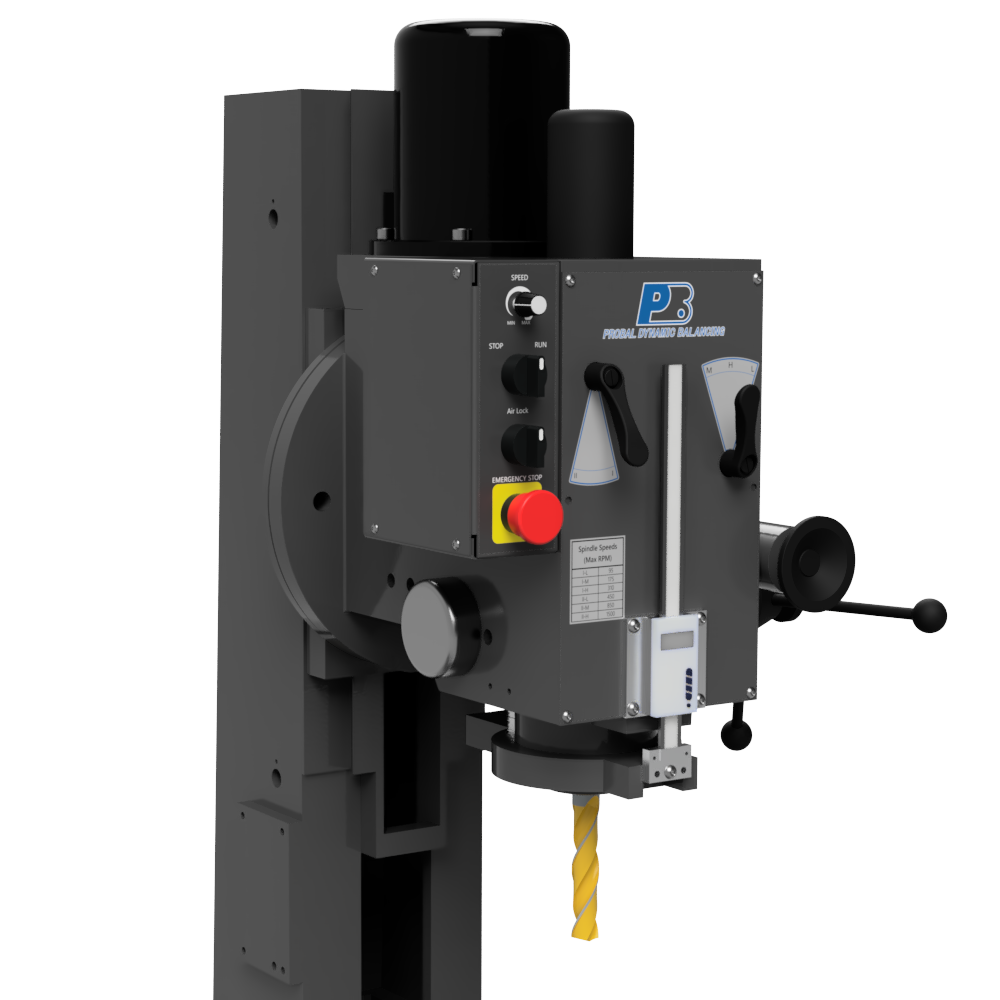

- Gear Driven High Torque Drill Unit

- One Heavy Metal Drilling and Installation Stand

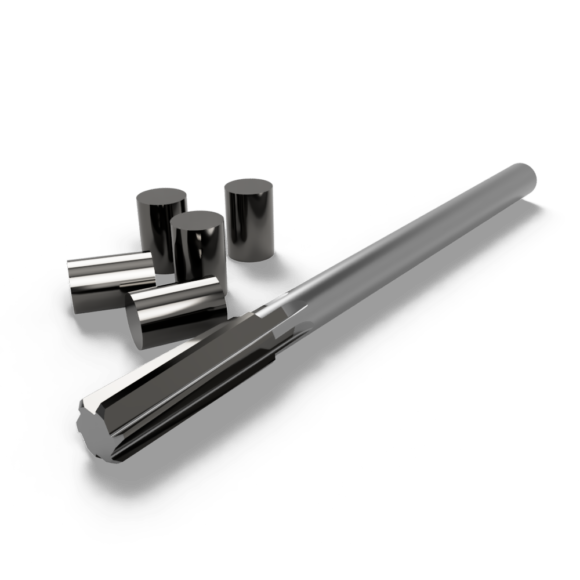

- Deluxe Tooling Package

- Spade Drill

- Reamer

- Heavy Metal Starter Kit

- Precision Linear Rail on All Traversable Components

- Calibration Proving Rotor

PROCESS OF BALANCING A CRANKSHAFT

Balancing a crankshaft is an essential process in engine manufacturing and rebuilding. The crankshaft is a vital component of an engine, responsible for converting the reciprocating motion of the pistons into rotational motion. However, due to the nature of its operation, the crankshaft can generate vibrations and forces that can affect the overall performance and longevity of the engine. Therefore, it is crucial to properly balance the crankshaft to minimize these vibrations and ensure smooth operation.

The process of balancing a crankshaft involves carefully analyzing the weight distribution of the crankshaft and making adjustments to achieve a perfect balance. To begin with, the crankshaft is mounted on a balancing machine, which allows for precise measurements and calculations. The machine rotates the crankshaft at various speeds, while sensors detect any imbalances.

Once the initial measurements have been taken, the next step is to determine where weight needs to be added or removed from the crankshaft. This is done by either drilling or milling holes in specific areas or by adding weights to counterbalance the existing weight distribution. The objective is to achieve an equal weight distribution around the axis of rotation, minimizing any vibrations or forces that could negatively impact engine performance.

ACHIEVE PERFECT BALANCE WITH PRECISION AND EASE

At ProBal Dynamic Balancing, we prioritize quality and precision for your crankshaft balancing needs. Our machines are powered by the innovative Overhead Drive system, ensuring swift operations, complemented by the convenience of a Removable Stand for easy Heavy-Metal installation. The robust design incorporates Linear Rails on all traversable components, delivering unmatched rigidity and minimal deflection during drilling. Paired with our Gear Driven Drill Press, which offers immense torque, drilling becomes an effortless task.

Beyond exceptional functionality, ProBal guarantees affordability without compromising on quality. With state-of-the-art touch screen controls and a competitively priced model, we provide unmatched value. Choose ProBal Dynamic Balancing for excellence, innovation, and a commitment to setting new industry standards.

ADVANCED LINEAR GUIDEWAY TECHNOLOGY

EXCLUCIVE DRIVE SYSTEM

PROVING ROTOR INCLUDED!

GEARED DRILLING HEAD

Precision linear guideways are incorporated into the traverse system for both the overhead drive and drilling system. No more round rails that have excessive clearance and flex. This technology allows us to set the standard for drill rigidity and effortless positioning for easy and very accurate corrections.

HEAVY METAL DRILLING STAND

Crafted from thick gauge steel, this stand ensures a robust and sturdy platform, allowing for precise drilling and the seamless installation of heavy metal into counterweights. Its durability guarantees consistency and accuracy, vital for the longevity and performance of crankshafts. By detaching the stand, users gain access to a generous 5 ft base, accommodating longer workpieces with ease.

PROVING ROTOR INCLUDED!

- Carbide Inserted Spade Drill

- Precision Gram Scale

- Carbide-Tipped Reamer

- 5 Precut Heavy Metal Slugs

- Connecting Rod Weighing Fixture