The TS1000 BlockMaster

Automated Machine

- Have the ability but not the necessity of putting the cylinders at perfect center to center positions from whatever datum plane the operator desires whether from the dowel pin, main thrust surface, bell housing surface, etc…

- Alternatively have the ability to compensate for the wear in used blocks when centering and boring since most blocks will not “clean up” if attempting to correct the bore centers.

- Use the same program for all blocks as opposed to a different program for Chevys, Fords, Isuzu, etc…

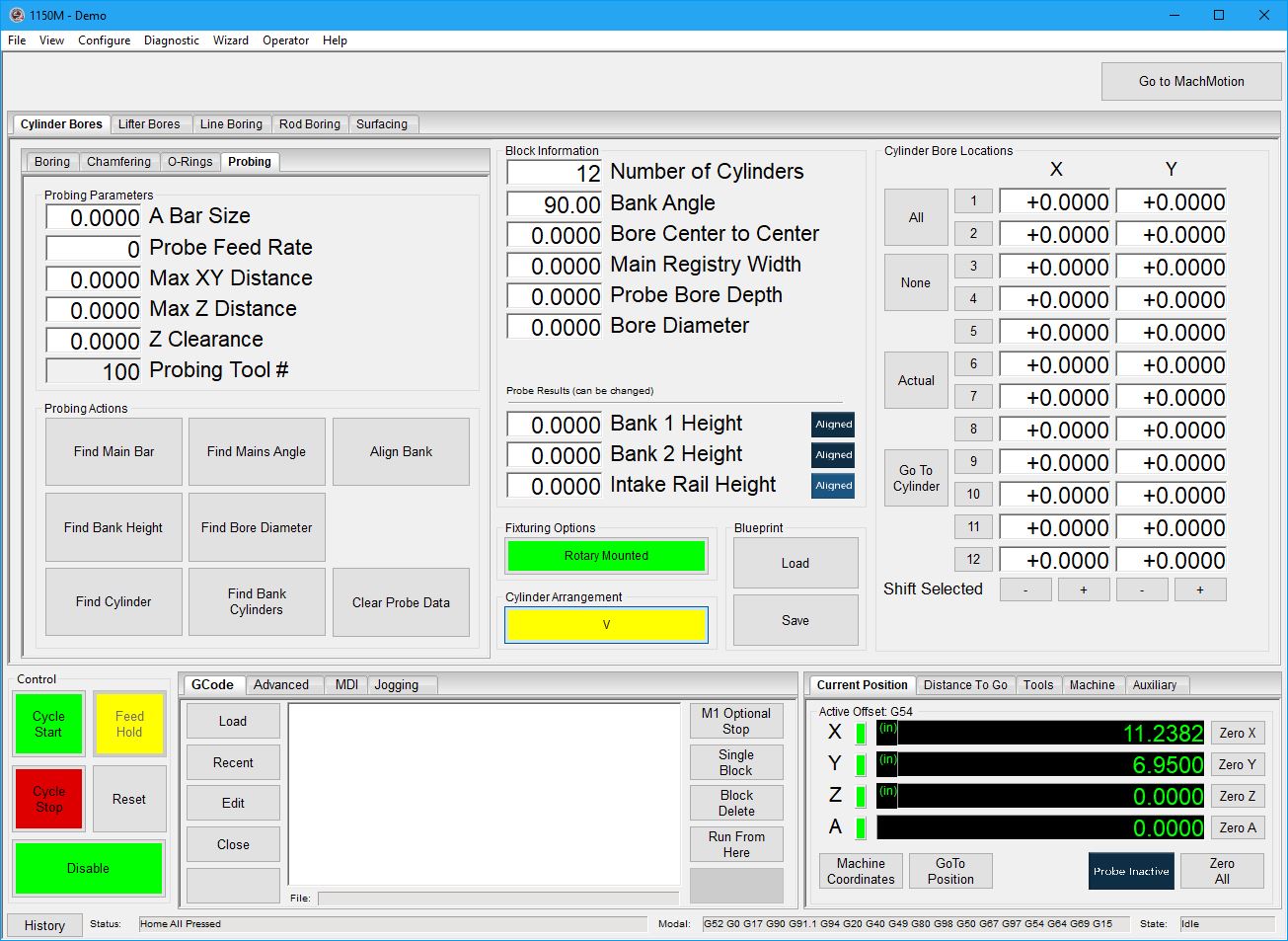

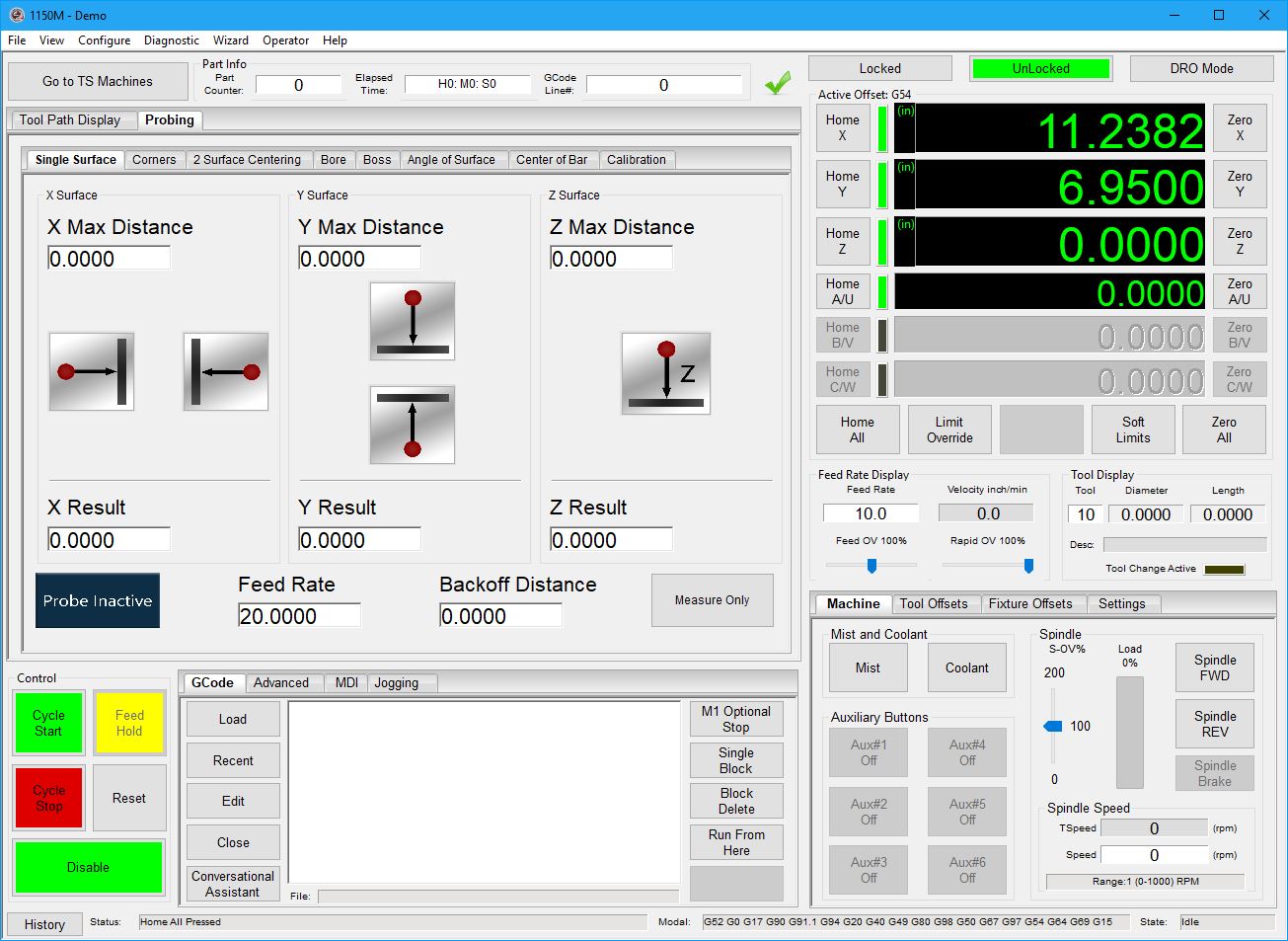

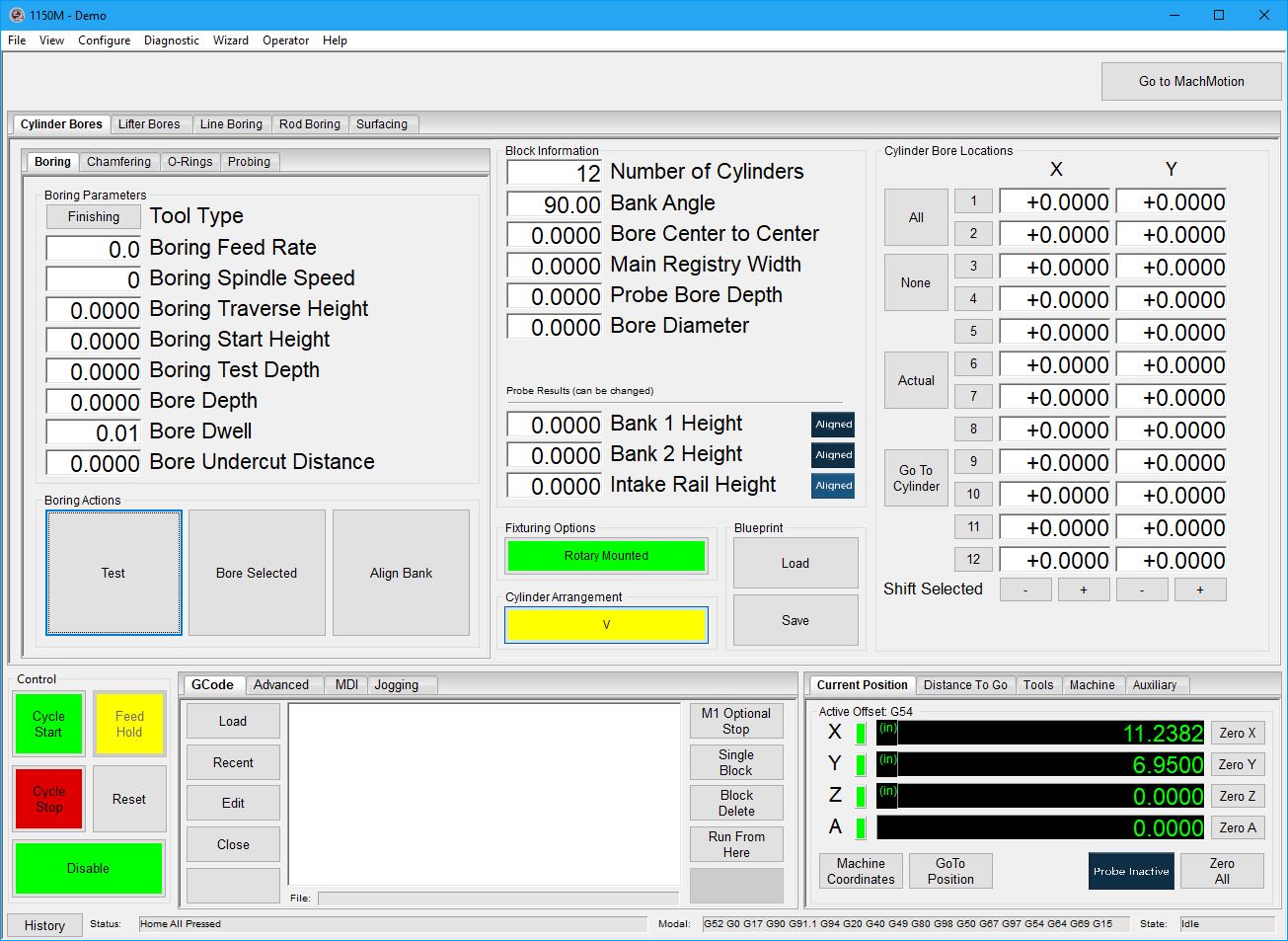

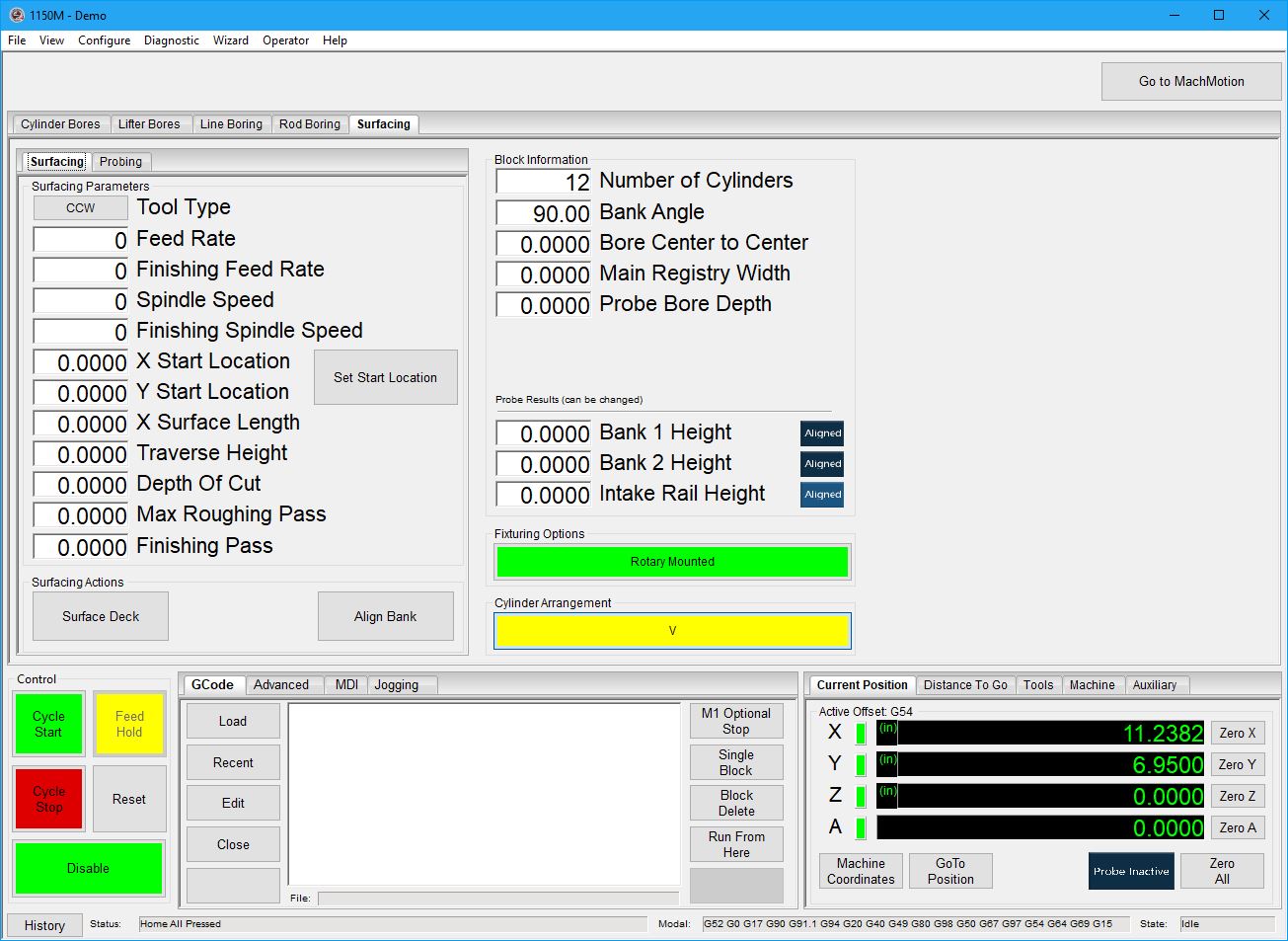

- Use and operator interface to lead the customer through the block boring and surfacing process without any knowledge of running a CNC control.

- Have the fastest floor to floor time possible on any CNC boring mill

- Have the most versatile system of any CNC boring mill on the market

- Use the probe to automatically display the size of the bores so no measuring of the cylinders by the operator is necessary.

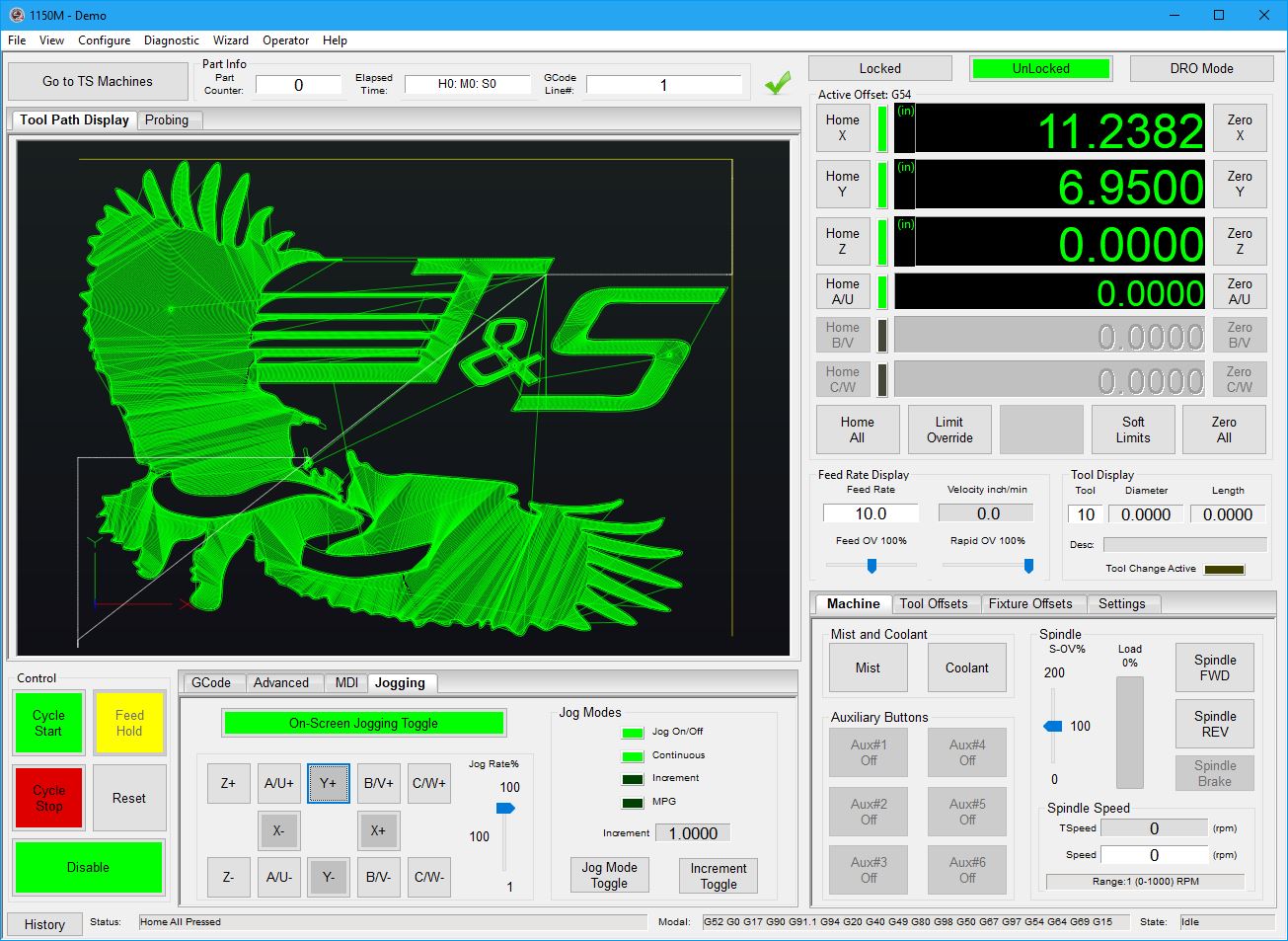

- Have a CNC boring mill capable of all the above and still capable of automatically machining parts with g-code programs generated by any cad/cam system an operator might have.

- Have the ability to engrave parts with no special programming tools.

- He works on anything that comes through the door.

- He needs to be able to have this CNC boring mill running with the least operator intervention possible so he can bore and surface (and cut lifter bores, notch pan rails for stroker cranks, etc…) while he is in the next room doing paperwork or helping the next customer.

- He does not have time to be changing out the fixture for different jobs. He needs the machine to be cutting metal.

- He needs to take his best operator (in many cases himself) and make him more efficient and more precise.

- He needs to greatly increase his cash-flow.

- He wants a show-piece CNC boring mill to impress his customers to bring in more work.

We have built a CNC boring mill for this customer. There are those who work on the same engine over and over or at least only about four different engines. For this we have a little different setup we can use that is dedicated to these engines. More of our customers work on any and everything and the blocks are usually well-worn. With the BlockMaster is doesn’t matter what your preference or workload is, it’s easy and affordable for YOU. This truly is the best value CNC boring mill on the market today.

Specifications

| Control | Automatic with Full G-Code CNC Capabilities |

| Routines Included | Block Boring, Surfacing, Lifter Bores and Probing |

| Touch Screen | 17" |

| Machine Weight | 9500 lbs (Depends on frame) |

| Table - Size | 56.7" x 18" |

| Table - T Slots | 3 Wide Slots for Generic Machine Work |

| Travel - Horizontal (X Axis) | 50" |

| Travel - In/Out (Y Axis) | 22" |

| Travel - Vertical (Z Axis) | 24" |

| Travel - Spindle Nose to Table | 15-39" |

| Spindle - Taper | CAT 40 |

| Spindle - Rotation Speed | 0 to 4000 RPM |

| Spindle - Motor | 7.5 hp |

| Tool Changer | Carousel Automatic Tool Changer (optional) |

| Air Draw-Bar for Tool Changes | Yes |

| Block Fixtures | Standard Inline and V-Block Included |

| Coolant Capacity | 30 Gallons |

| Cylinder Bore Range (with Optional Cutter Heads) | 2" - 5" capable |

| Performance - Rapid Travel (X, Y, Z) | 400 I/min |

| Dimensions - Machine | 143.7” L x 93.7” W x 108.7" H |

| Electrical Requirements | 208-240V, 60A, 50/60Hz, 3Ph |

| Air Requirements | cfm @ 90 psi |

| Paint Color | White |

| Control | Automatic with Full G-Code CNC Capabilities |

| Routines Included | Block Boring, Surfacing, Lifter Bores and Probing |

| Touch Screen | 432mm |

| Machine Weight | 4309 kgs |

| Table - Size | 1440mm x 457mm |

| Table - T Slots | 3 Wide Slots for Generic Machine Work |

| Travel - Horizontal (X Axis) | 1270mm |

| Travel - In/Out (Y Axis) | 559mm |

| Travel - Vertical (Z Axis) | 610mm |

| Travel - Spindle Nose to Table | 381-990mm |

| Spindle - Taper | CAT 40 |

| Spindle - Rotation Speed | 0 to 4000 RPM |

| Spindle - Motor | 7.5 hp |

| Tool Changer | Table-Mounted Automatic Tool Changer (optional) |

| Air Draw-Bar for Tool Changes | Yes |

| Block Fixtures | Standard Inline and V-Block Included |

| Coolant Capacity | 113.5 Liters |

| Cylinder Bore Range (with Optional Cutter Heads) | 50.8mm - 127mm capable |

| Performance - Rapid Travel (X, Y, Z) | 10160mm/min |

| Dimensions - Machine | 3650mm L x 2380mm W x 2761mm H |

| Electrical Requirements | 208-240V, 60A, 50/60Hz, 3Ph |

| Air Requirements | cfm @ 90 psi |

| Paint Color | T & S New Holland Ford Blue |