ProBal DBS Dynamic Balancing

Machine Electronics Upgrade

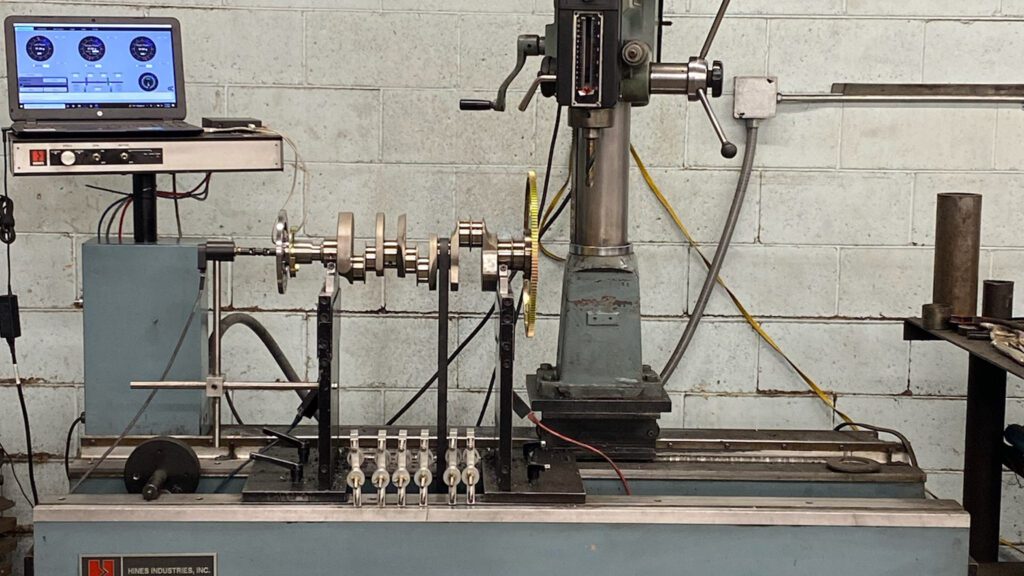

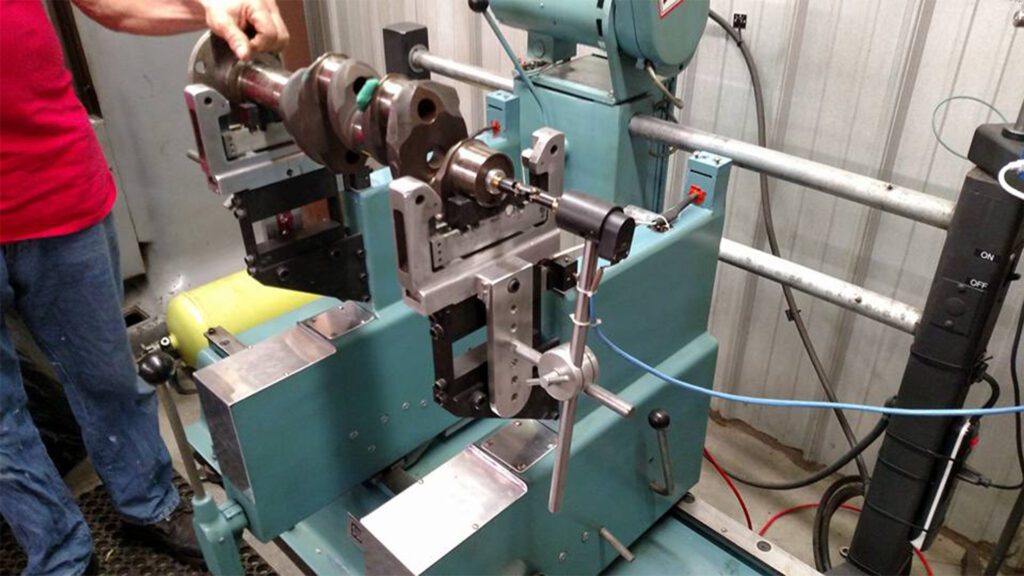

While no machine is built to last indefinitely, it doesn’t mean it’s destined for the scrapyard. ProBal offers the option to upgrade the electronics of any existing dynamic balancing machine. Often, manufacturers cease support for older equipment, but we can rejuvenate these machines by fitting them with new sensors, encoders, and drive systems.

If your system is out of date, unreliable, or has stopped functioning, purchasing a new machine isn’t your only recourse. We specialize in minimizing your operational disruptions and frustration by upgrading the electronics and controls of your existing machine. This allows you to maintain the familiarity of your current machine while benefiting from the technology and functionality of a new one.

Choosing to upgrade your existing machine is not only cost-effective compared to purchasing a new or used one, but it also avoids the complications associated with acquiring new equipment.

Contact us today for an evaluation of your machine and to explore the various upgrade options we offer.

UPGRADES AVAILABLE FOR BALANCING MACHINES OF ALL BRANDS

- Stewart Warner

- Pro-Bal

- Hines

- Winona

- Balance Technology

- Fentech

- Schenck

- Hofmann

- CWT

- IRD

- Dynamics Research

- JP Balancing

- Abro

- Gilman

- Gisholt

- Balanstar

- CEMB

- Coetz

SPECIAL FEATURES

- Diverse Control Solutions

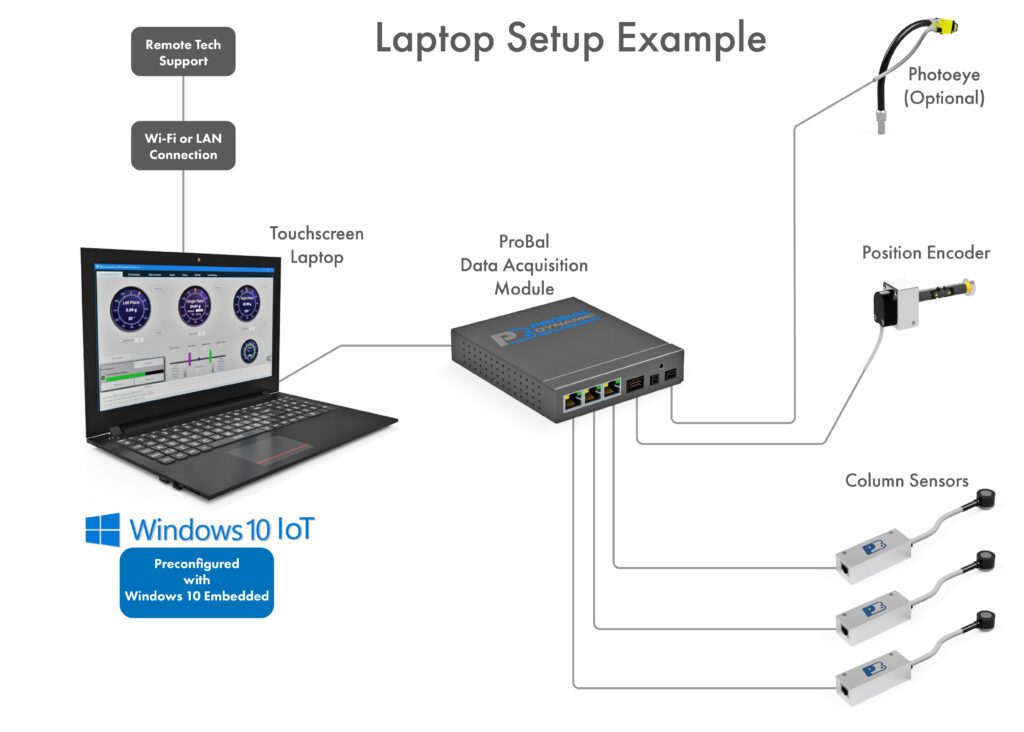

- Laptop with Independent Drive System

- Integrated All-In-One Computer

- Rolling Console

- Rapid Sample Times

- Tailored Solutions

- Compatible with All Hard-Bearing Balancing Machines

- Conversion Options for Soft-Bearing Machines

- Single, Dual, or Triple Column Configurations

- Advanced Hard-Bearing Sensors and Electronics

- Permanent Calibration

- Eliminates the Need for Test Weights

- Windows 10 IoT Embedded Operating System

- Control Windows Updates

- Computer feels faster

- On-Site Setup and Training available

OVERVIEW

A retrofit for a balancing machine is a comprehensive process that entails updating various key components such as sensors, encoders, computers, wiring, and motor drives with modern and efficient parts. T&S can install ProBal electronic retrofits on any mechanically sound dynamic horizontal or vertical balancing machine, effectively revitalizing older frames. Often, machines begin to falter primarily due to outdated electronics, and a ProBal retrofit kit can extend their operational life by a decade or more, ensuring continued performance and reliability.

What advantages can be gained from retrofitting a dynamic balancing machine?

- Cost savings compared to investing in a new machine.

- Enhanced accuracy and sensitivity with modern electronics, surpassing old and outdated components.

- On-site retrofits eliminate the expenses and hassle associated with rigging and transportation.

- Significantly reduced downtime compared to the delivery time for a new machine.

- A lifetime warranty on core electronics and a one-year warranty on sensors and computer parts and labor.

T&S is dedicated to ensuring the longevity and precision of your machines through a commitment to lifetime software updates. This ensures your equipment remains current and accurate. Our support team, with their extensive knowledge in various balancing applications, is ready to assist you with advice tailored to your specific parts and tasks. We are committed to guiding you in achieving work that meets current industry standards, thereby extending the lifespan of your balancing machines, even those dating back to the 1950s!

GET A QUOTE!

1

REQUEST A QUOTE

Talk with our expert sales engineers to discuss your requirements. We are dedicated to providing you with the most effective solution, tailored to your needs, at a significantly lower cost than acquiring a new machine.

2

ARRANGE YOUR INSTALL

We offer a comprehensive turnkey package to ensure you’re operational again in no time. Whether you opt for a self-installation of your new control or prefer to have one of our skilled technicians on-site, we’re committed to making your upgrade process as seamless and stress-free as possible.

3

RUN WITH CONFIDENCE

Rest assured that with your new control, you’re not just getting one of the finest balancing systems on the market, but also access to world-class support that’s just a phone call away.

STATE-OF-THE-ART CONTROL SOLUTIONS

Based on your specific machine type and manufacturing preferences, T&S provides various options for control panels and interfaces. Our offerings include industrial-grade metal enclosures, Windows 10 IoT Embedded Operating System, and touch screen capabilities, ensuring the most effective balancing software solutions in any setting. Whether you need a straightforward, cost-effective laptop-based balancing system or a comprehensive mobile console with integrated drive motor electronics, we’re here to assist you in choosing the most suitable control interface for your needs.

INSTALLATION

TURNKEY INSTALL:

Our skilled team handles it all. Simply provide us with details about your machine, and our experienced technicians will take care of getting it operational for you.

SELF-INSTALL:

ONSITE COMMISSIONING:

Once you complete the self-installation and your machine is set up for use, a member of our team can visit your facility. They will ensure proper calibration, assess the operating performance, and provide personalized training to your operators, guaranteeing everything runs smoothly.

SHIP YOUR MACHINE:

REMOTE SUPPORT

Get help instantly with Remote Log In Support (Anydesk)

Our technicians have the capability to remotely access your computer and view your control interface exactly as you see it. This enables us to swiftly diagnose and resolve issues, saving you from the unnecessary expenditure and time involved in an on-site visit for problems that can be easily missed during a phone conversation. If an on-site visit is preferred or necessary, this approach ensures that we are better prepared and informed, allowing our technicians to quickly address and resolve the issues upon their arrival.

SPEED UP YOUR PROCESS

Enhance your current machine with a suite of advanced features – including a built-in ISO tolerance calculator, drill correction calculations, customizable reports, real-time correction positioning, options for single or dual plane balancing scenarios, measurement history, keyway compensation, tooling compensation, and more. All these functionalities are integrated into a very intuitive and elegantly designed interface!